About

About PEI Bag Co.

Our customer service folks are on hand to work with clients to determine and provide the type and quantity of packaging your business requires.

Our Core Values

PEI Bag Co. will add value to our customer’s business by providing packaging products, packaging machinery, and industry-related problem resolution services.

- We value our people.

- We understand our customer relationships are the foundation of our success.

- We pride ourselves on the quality of our products, expertise, and service.

- We act with integrity and are a trusted partner.

- We strive to provide environmentally conscious solutions and to reduce our carbon footprint.

- We are committed to prosperity for our employees, customers, shareholders, and our community.

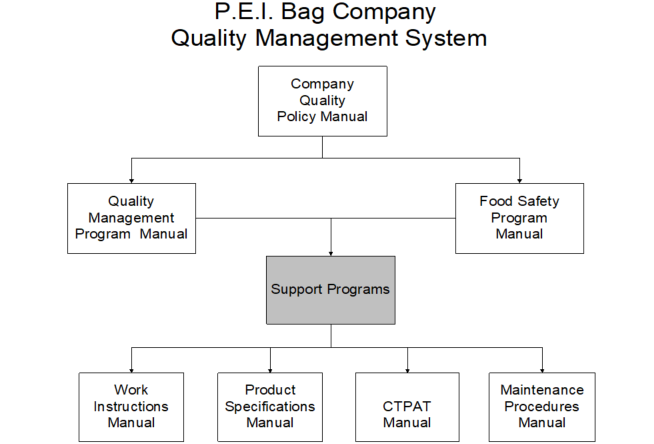

Quality System Overview

To meet customer and marketplace expectations, the PEI Bag Company has strategically decided to demonstrate its commitment to quality by certifying its quality system to the standard of the Global Food Safety Initiative (GFSI).

For a packaging company, this level of globally recognized quality is achieved through the design and implementation of a Quality System that meets the stringent standards of the IFS PACsecure Packaging Standard which falls under the umbrella of the GFSI.

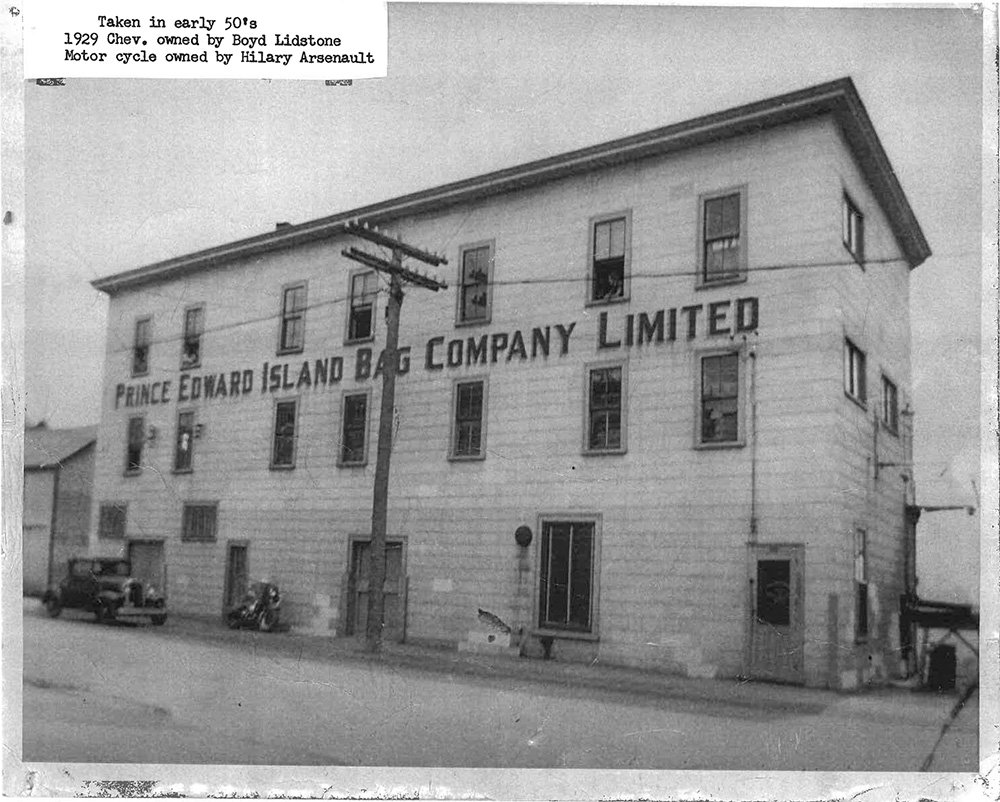

Company History

Certifications

- IFS PACsecure is a risk-based Standard to assess packaging material manufacturers.

- It is a product and process certification that offers a number of benefits to companies striving for excellence in quality and safety, and seeking a competitive advantage in their marketplace.

- The Standard has a strong focus on checking compliance with customer requirements.

- Question answered by IFC PACsecure audit: Is a supplier capable of delivering safe products according to the agreed product specification?

- The requirements of IFS PACsecure are more flexible than other standards

- IFS PACsecure certification is granted based on the degree of fulfillment.

- The Standard also considers compliance to customer requirements.

- Additionally, the checklist of IFS PACsecure contains example questions to be addressed to the company during the audit, as well as examples for Major and KO situations.

- The IFS evaluation system shows to what extent the requirements are met, giving a clearer view on the status quo of the audited company.