Packaging Equipment

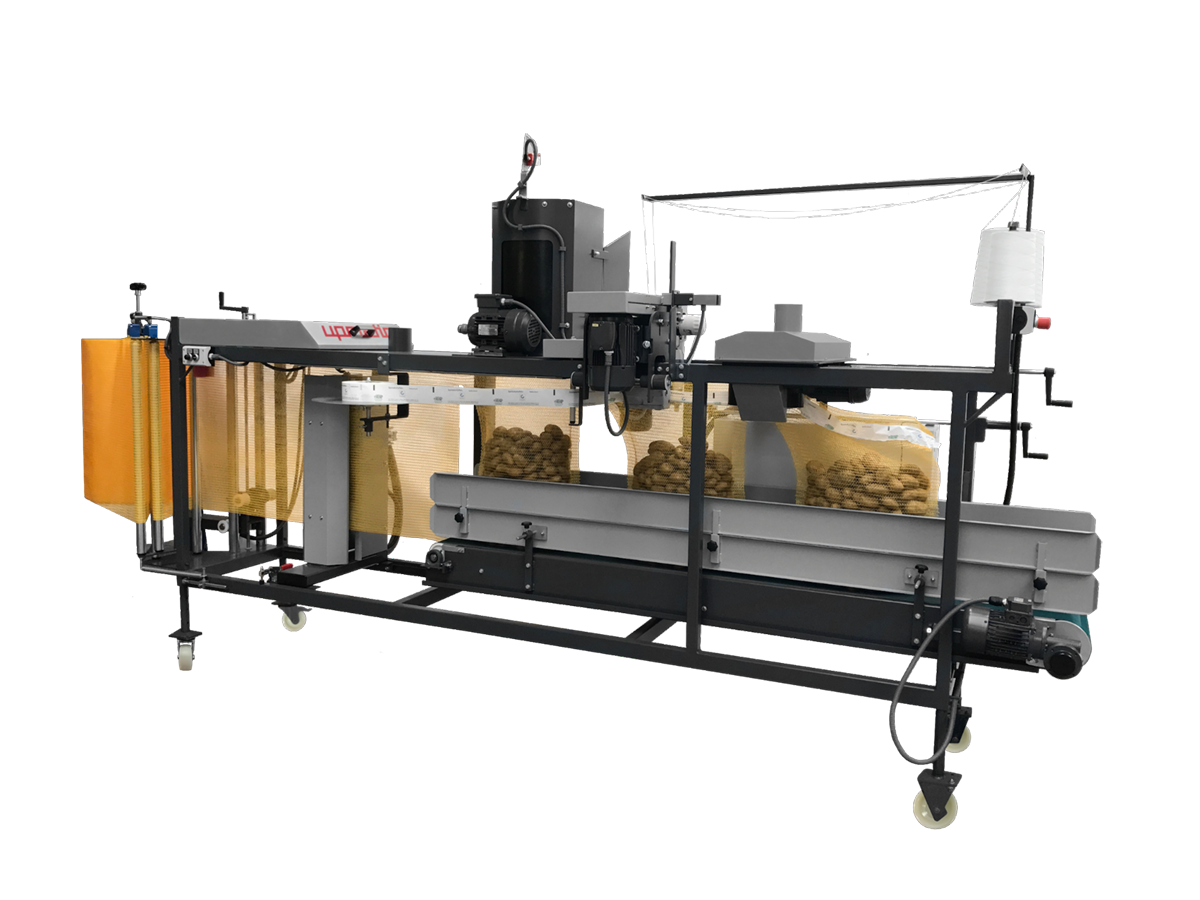

Upmann 2112

Fully automatic filler sealer for netting bags capable of holding contents weighing from 2.5 to 50 kg. Depending on the choice of packaging material, it is suitable for all food and non-food products in lump or granular form.

The Upmatic 2112 is easy to operate and is very robust. The roll of packaging material is separated into the desired length (except for a guide strip) by a thermal cutting process and is positioned under the feed hopper. Once filled, the sack is labelled and sealed by stitching while still on the conveyor.

The centrally lubricated industrial sewing machine is incorporated as standard. As the final process, the guide strip and the marking tape are separated between the roll pairs. All work processes are infinitely variable and precisely synchronised with each other. No tools are needed to quickly adapt the machine to take different sack sizes.

The Upmatic 2112 is equipped with fixed and guide rollers and can be combined with all commercially available weighing and dosing machines.

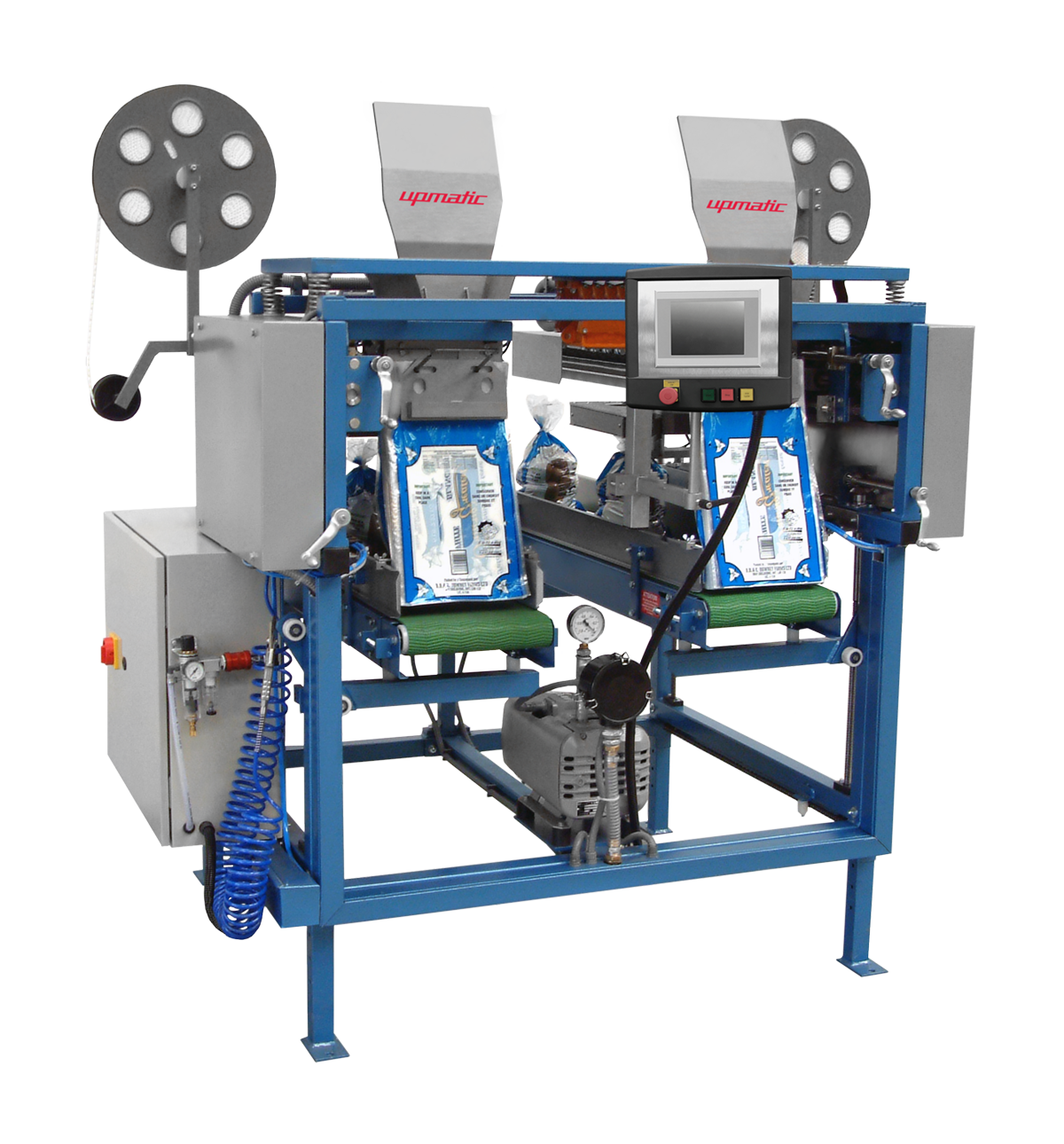

Upmatic 2402WB

The Upmatic 2402WB is a fully automatic filler sealer for film bags capable of holding contents weighing from 1 to 10 kg. Suitable for all food and non-food products in lump or granular form.

The Upmatic 2402WB is robust and easy to operate. The pre-formed film bags are taken from the magazine and placed under the feed hopper where they are opened pneumatically and filled. The bag is then closed. After filling, the bag is moved to the sealer, sealed and moved away from the machine.

All changes in settings for the various bag sizes are simple and do not require a tool. The supporting conveyor speed is infinitely variable.

The machine can be combined with all commercially available weighing and dosing machines.

Upmatic 2402 Wickett Bagger

The Upmatic 2402WB is a fully automatic filler sealer for film bags capable of holding contents weighing from 1 to 10 kg. Suitable for all food and non-food products in lump or granular form.

The Upmatic 2402WB is robust and easy to operate. The pre-formed film bags are taken from the magazine and placed under the feed hopper where they are opened pneumatically and filled. The bag is then closed.

After filling, the bag is moved to the sealer, sealed and moved away from the machine. All changes in settings for the various bag sizes are simple and do not require a tool. The supporting conveyor speed is infinitely variable.

The machine can be combined with all commercially available weighing and dosing machines.

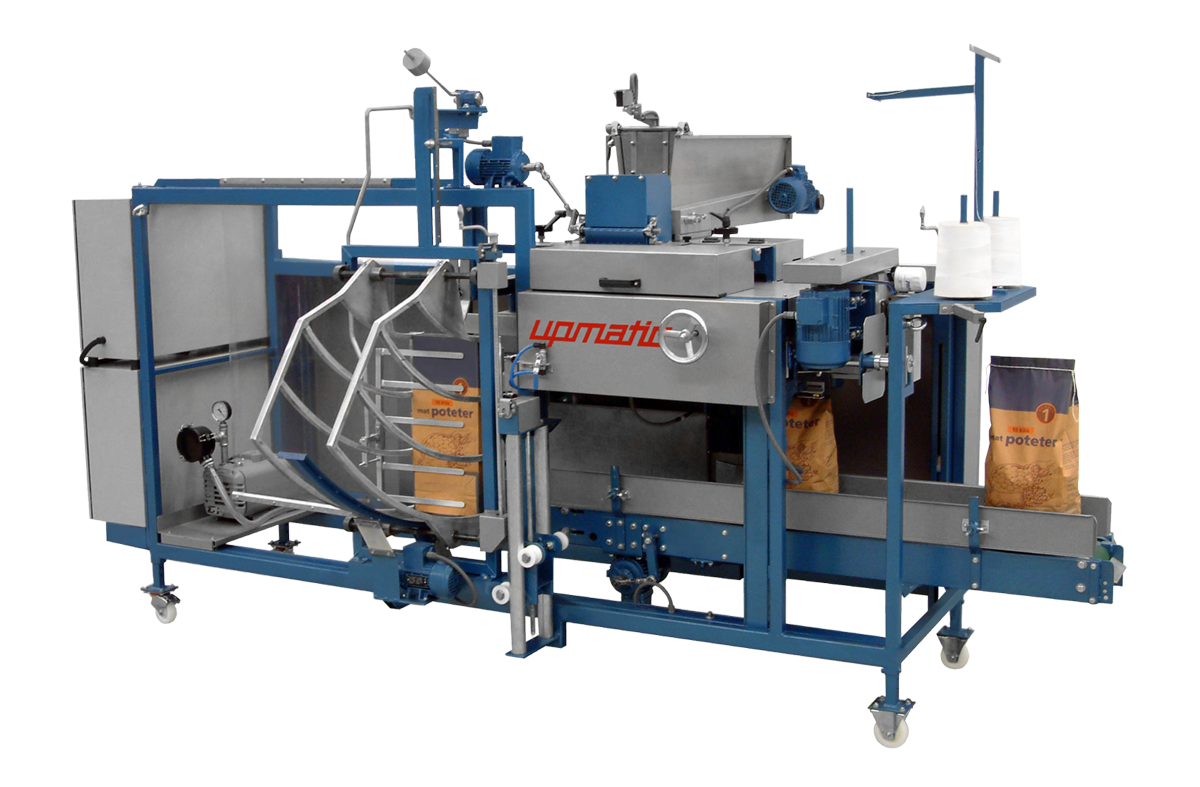

Upmatic 4125

The Upmatic 4125 is a fully automatic filler sealer for paper bags with or without a carrying handle capable of holding contents weighing from 5 to 25 kg. Suitable for all food and non-food products in lump or granular form.

The Upmatic 4125 is robust and easy to operate. The paper bags are taken from the magazine and placed under the feed hopper, opened pneumatically and filled. After filling, the bag is closed pneumatically, stitched and moved away from the machine. All changes in settings for the various bag sizes are simple and do not require a tool. The supporting conveyor speed is infinitely variable. A centrally lubricated industrial sewing machine, an accumulation conveyor and a vacuum pump are incorporated as standard.

Die Upmatic 4125 is equipped with fixed and guide rollers and can be combined with all commercially available weighing and dosing machines.

Upmatic 4210 3lb – 20lb paper

The Upmatic 4210 is extremely rugged and easy to operate. Paper bags are taken from the magazines and conveyed under the filling station, they are opened pneumatically and filled.

After the filling the bags are pneumatically closed, sewn up and conveyed. All adjustments to different bag sizes can easily be made without tools. The support belt speed is easily adjustable.

This is suitable for paper sizes from 3lb–20lb sizes.

Upmatic Semi Auto 3015

The Upmatic 3015 is our semi-automatic sealing machine including a high-quality industrial sewing machine from Fischbein. It is suitable for all kinds of granular and coarse products of the food and non-food industry. Easy handling, reliability, and self-explanatory work steps are only a few of the many excellent features the Upmatic 3015 has to offer.

Semi-automatic means that some work steps require active involvement such as placing each bag in the funnel-shaped clamp or taking the flawless finished product off the belt conveyor. All other work steps such as the filling process are either completed in tandem with a weighing machine, or by the Upmatic 3015 itself.

To guarantee absolutely convenient handling at all times, the Upmatic 3015’s settings can be adjusted while in operation. Moreover, its industrial sewing machine can be swivelled out. This special feature extremely simplifies maintenance, threading, and potential needle changes.

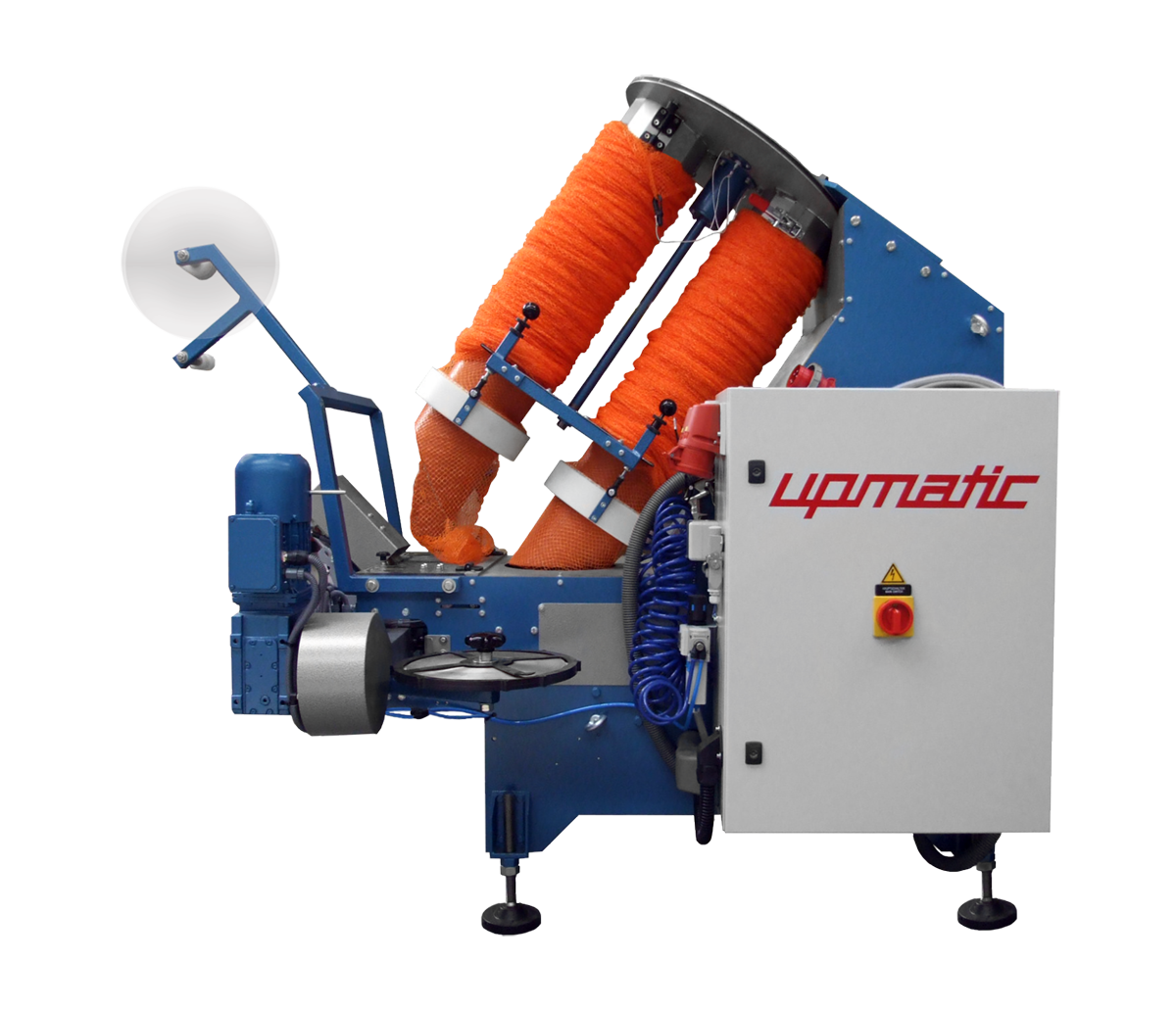

Upmatic 3006

The Upmatic 3006 is a fully automatic double tube net clipping machines for bag weights from 0.5 to 5kg. Suitable for all small and large products in the food and non-food industries. The Upmatic 3006 is easy to operate and very robustly built.

The endless net is automatically pulled from the tube, sealed at the bottom, filled with the product and then clipped at the top and marked. The entire process is fully automatic and enables high packing rates to be maintained. As soon as the net has been filled and sealed on one of the tubes, the machine stops the process for a moment, swings the other tube into the filling position and then continues the filling and sealing process—completely automatically. A new endless tube can be fitted into an empty tube while the machine is running.

The height of the Upmatic 3006’s swivelling feet can be adjusted.

In the interest of our customers, we must reserve the right to make technical changes.